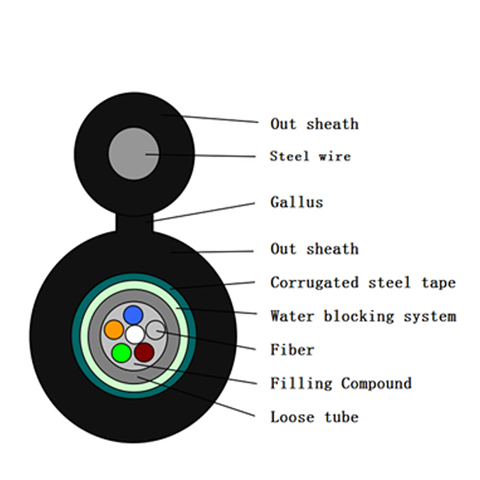

Figure 8 self-supporting Center Tube Optical cable GYXTC8S

The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic, the tubes are filled with a water-resistant filling compound. Loose tubes filled with water proof compound to ensure compact and longitudinally water blocking, this part of cable accompanied with the wires as the supporting part are completed with a polyethylene(PE) sheath to be figure 8 structure.

This specification covers the general requirements of Figure 8 self-supporting cable for aerial .

· High tensile strength of stranded wires meet the requirement of self-supporting

· and reduce the installation cost.

· Good mechanical and temperature performance

· High strength loose tube that is hydrolysis resistant

· Special tube filling compound ensure a critical protection of fiber

· The following measures are taken to ensure the cable watertight:

· Loose tube filling compound

· 100% cable core filling

· steel tape moisture barrier

· and reduce the installation cost.

· Good mechanical and temperature performance

· High strength loose tube that is hydrolysis resistant

· Special tube filling compound ensure a critical protection of fiber

· The following measures are taken to ensure the cable watertight:

· Loose tube filling compound

· 100% cable core filling

· steel tape moisture barrier

Cable construction details :

| Number of fiber | 2~12core | |||||||

| Moisture Barrier | Water blocking system | |||||||

| Central strength member | material | FRP | ||||||

| diameter | 1.4mm | |||||||

| Mental strength member | material | Galvanized steel wire | ||||||

| diameter | 1.2 mm | |||||||

| Loose tube | material | PBT | ||||||

| diameter | Ф2.0mm | |||||||

| Cable filling | material | Cable filling compound | ||||||

| Outer sheath | material | PE | ||||||

| diameter | 1.70±0.2mm | |||||||

Fiber color

| Number of fiber per tube 8cores |

1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | Grey | White | |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Red | Black | Yellow | Violet | Pink | Aqua |

Cable Mechanical characteristic

| core | Cable diameter | weight | |||||

| 2 cores to24 cores | 3.2*7.2 ±0.1mm | 90±2 kg/km | |||||

| Min Bending Radius(mm) | Long term | 10D | |||||

| Min Bending Radius(mm) |

Short term | 20D | |||||

| Min allowable Tensile Strength(N) |

Long term | 600 | |||||

| Min allowable Tensile Strength(N) |

Short term | 1500 | |||||

| rush Load (N/100mm) | Long term | 600 | |||||

| Crush Load (N/100mm) | Short term | 1500 | |||||

| Operation temperature (℃) |

-40+70 | ||||||

| Installation temperature(℃) |

-15+60 | ||||||

Fiber characteristic

| Fiber style | Unit | SM G652 |

SM G652D |

MM 50/125 |

MM 62.5/125 |

MM OM3-300 |

|

| condition | nm | 1310/1550 | 1310/1550 | 850/1300 | 850/1300 | 850/1300 | |

| attenuation | dB/km | ≤ | ≤ | ≤ | ≤3.0/1.0 | ≤3.0/1.0 | |

| 0.36/0.23 | 0.34/0.22 | 3.0/1.0 | ---- | ---- | |||

| Dispresion | 1550nm | Ps/(nm*km) | ---- | ≤18 | ---- | ---- | Dispresion |

| 1625nm | Ps/(nm*km) | ---- | ≤22 | ---- | ---- | ||

| Bandwith | 850nm | MHZ.KM | ---- | ---- | ≧400 | ≧160 | Bandwith |

| 1300nm | MHZ.KM | ---- | ---- | ≧800 | ≧500 | ||

| Zero dispersion wavelength | nm | 1300-1324 | ≧1302, ≤1322 |

---- | ---- | ≧ 1295, ≤1320 |

|

| Zero dispresion slope | nm | ≤0.092 | ≤0.091 | ---- | ---- | ---- | |

| PMD Maximum Individual Fibr | ≤0.2 | ≤0.2 | ---- | ---- | ≤0.11 | ||

| PMD Design Link Value | Ps(nm2*k m) |

≤0.12 | ≤0.08 | ---- | ---- | ---- | |

| Fibre cutoff wavelength λc | nm | ≧ 1180, ≤1330 |

≧1180, ≤1330 |

---- | ---- | ---- | |

| Cable sutoff wavelength λcc |

nm | ≤1260 | ≤1260 | ---- | ---- | ---- | |

| MFD | 1310nm | um | 9.2+/-0.4 | 9.2+/-0.4 | ---- | ---- | ---- |

| 1550nm | um | 10.4+/-0.8 | 10.4+/-0.8 | ---- | ---- | ---- | |

| Numerical Aperture(NA) |

---- | ---- | 0.200+/ -0.015 |

0.275+/-0. 015 |

0.200+/-0 .015 |

||

| Step(mean of bidirectional measurement) |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| Irregularities over fiber length and point |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| Dicontinuity | |||||||

| Difference backscatter coefficient |

dB/km | ≤0.05 | ≤0.03 | ≤0.08 | ≤0.10 | ≤0.08 | |

| Attenuation uniformity | dB/km | ≤0.01 | ≤0.01 | ||||

| Core dimater | um | 50+/-1.0 | 62.5+/-2.5 | 50+/-1.0 | |||

| Cladding diameter | um | 125.0+/-0.1 | 125.0+/-0.1 | 125.0+/-0.1 | 125.0+/-0.1 | 125.0+/-0.1 | |

| Cladding non-circularity | % | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | |

| Coating diameter | um | 242+/-7 | 242+/-7 | 242+/-7 | 242+/-7 | 242+/-7 | |

| Coating/chaffinch concentrically error |

um | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | ≤12.0 | |

| Coating non circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | ≤6.0 | ≤6.0 | |

| Core/cladding conentricity error | um | ≤0.6 | ≤0.6 | ≤1.5 | ≤1.5 | ≤1.5 | |

| Curl(radius) | um | ≤4 | ≤4 | ---- | ---- | ---- | |

Package

| 1.Packing material: Wooden drum | |||||||

| 2.Packing length: standard length of cable shall be 2 km. Other cable length is also availabler | |||||||

| if required by custome |

Cable marking and cable reel marking

The cable sheath shall be marked with white characters according to customer's requirement.

Chinese

Chinese English

English